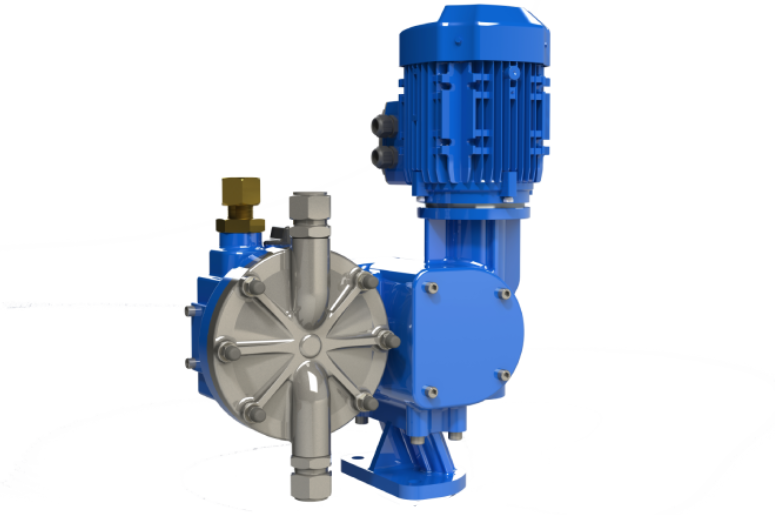

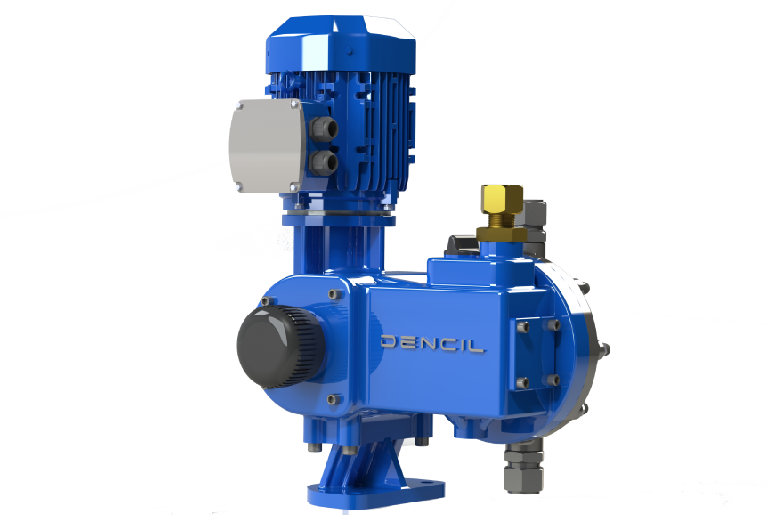

DIAPHRAGM PUMPS are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Diaphragm pumps have grown in significance recently, primarily due to environmental concerns. As a substitute for water jet vacuum pumps, diaphragm pumps don't generate any waste. When compared to a water jet pump, a diaphragm vacuum pump can reduce operating costs by up to 90%. Diaphragm pumps have a completely oil-free pumping chamber in contrast to rotary vane pumps. Oil-immersed shaft seals are not necessary by design. Her you can find Advanced Diaphragm Pump Manufacturer in India.

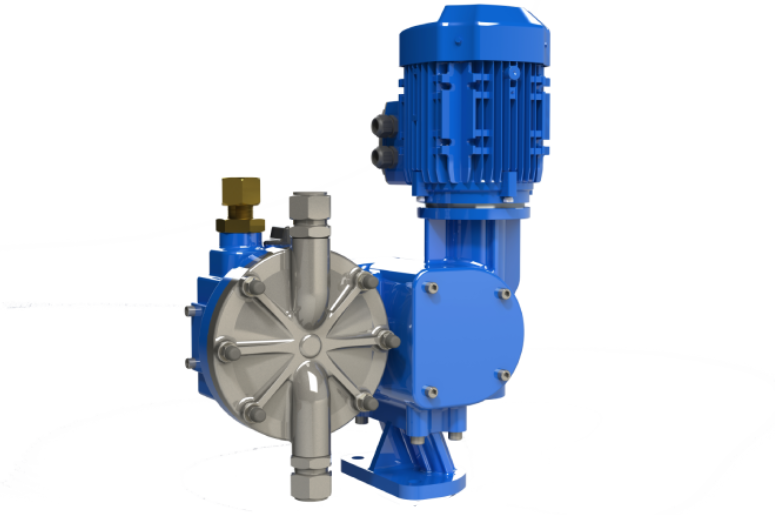

We offer technically advanced Mechanical Operated Diaphragm Pumps which are widely in demand in market because of low maintenance requirement. Providing absolute solution for batching operation, our pumps are based on simple and robust crank mechanism or spring return mechanical diaphragm pump. Being developed for handling corrosive liquid and those containing suspension of abrasive solids the pumps use mechanically-actuated diaphragm to combine the characteristics of a plunger pump (linear flow rate) with the sealing advantages of a diaphragm pump.